Understanding the distinctions between methionine sources availability in the animal feed additive sector

Methionine is a vital amino acid for poultry, swine, and dairy cattle. These animals cannot produce it on their own and must acquire it through their diet. Methionine is essential for protein synthesis, and in poultry and swine, it is frequently the first or second limiting amino acid. A deficiency in methionine can impede growth and overall performance. Dairy cattle also gain from methionine supplementation, especially concerning milk production and protein synthesis. Beyond being a protein component for meat, eggs, and milk, methionine is involved in methylation reactions and the production of antioxidants like glutathione and taurine. Most of animal feed formulations are derived from plants, and these plant sources typically contain low levels of methionine and cysteine Thus, incorporating methionine into animal feed is crucial. Synthetic sources of methionine have been employed to meet nutritional needs and improve the growth and production efficiency of animals.

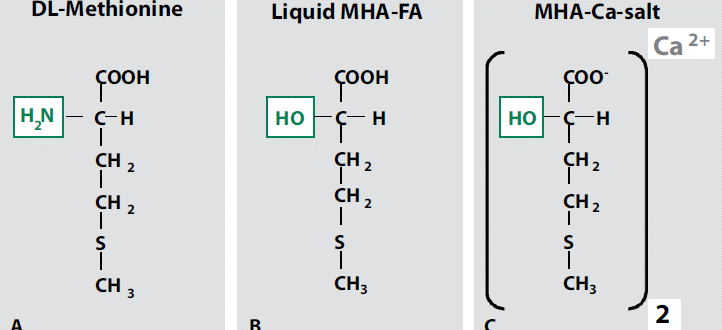

As the global demand for methionine continues to grow significantly, it is crucial to comprehend the distinctions among the commercially available sources currently present in the market. Various products commercially available that provide Methionine include DL-Methionine and L-Methionine. However, the market also features MHTBA (2-hydroxy-4-(methylthio) butanoic acid), which is NOT methionine itself but serves as a precursor to methionine. MHTBA products come in two forms: one known as MHA-FA (Methoxy Hydroxy Analogue Free Acid), which is liquid, and the other as MHA-Ca (Methoxy Hydroxy Analogue Calcium), which is in powder form.

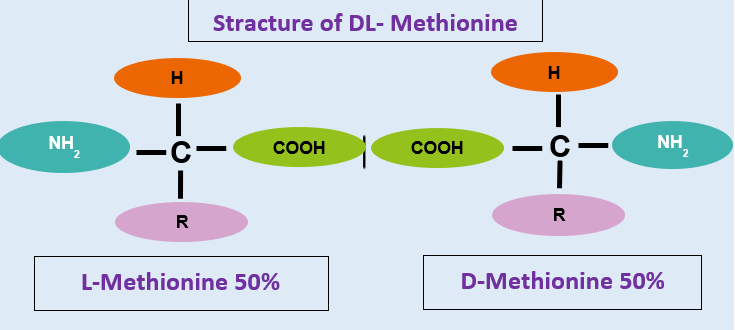

- DL-Methionine

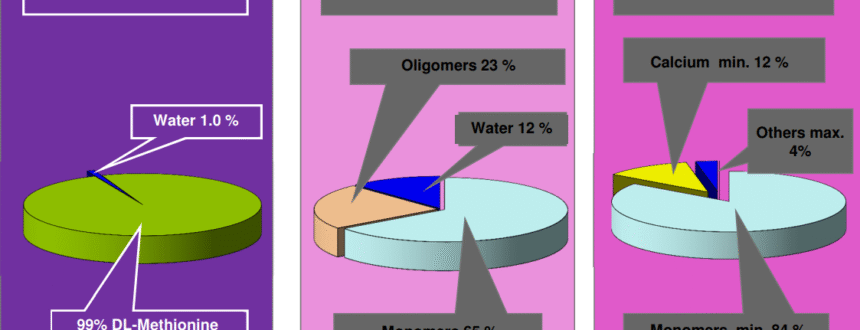

DL-Methionine is a crystalline products composed of 99% methionine and 1% water. It has the two isomers of methionine namely L- and D-Isomers, of which the L-form predominates in nature. Therefore, DL-methionine is 50:50 mixture of the D and L isomers of Methionine and is the most established commercial Methionine source in the market. Both forms can be metabolized in animals by a DL-racemase and many studies since 1943 have shown that there is no significant difference in using L- or DL-methionine in poultry diet (Goodson et al. 2012). Generally, animals can utilize the isomers of Met for protein synthesis, because of the unique enzymatic pathways to convert D-Met isomers to L-Met Isomer in the liver and kidney (Baker, 2006; Thwaites and Anderson, 2007).

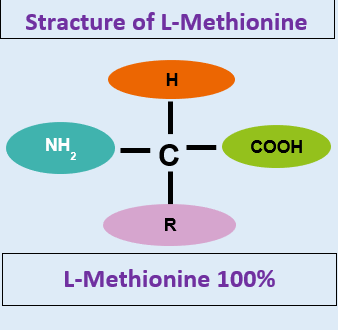

- L-Methionine

L-Methionine is a crystalline products composed of 99% methionine and 1% water. It only contains the natural isomer L (100% L-isomers) and a transamination of the D-to the L-isomer is not needed. L-Methionine and DL-Methionine have the same nutritional value, and there is no significant benefit to feeding L-Methionine compared to DL-Methionine.

DL-Methionine Versus L-Methionine

Both DL-Methionine and L-Methionine are crystalline substances consisting of 99% methionine and 1% water. L-Methionine contains 100% L-isomers, while DL-Methionine comprises 50% D- and 50% L-isomers. Both D- and L-isomers are effectively transported to the liver and kidneys through the bloodstream for utilization by animals. The dietary D-isomers of DL-Methionine must undergo conversion into L-isomers via two enzymatic reactions occurring in the liver, kidneys, and other organs. However, enzymes are abundantly present in the tissues of poultry, pigs, fish, and shrimp, ensuring that the conversion process from D-isomer to L-isomer in the animal body is not restricted in any manner. Studies indicate that this transformation DOES NOT adversely affect growth performance; thus, DL-Methionine and L-Methionine are nutritionally equivalent. Consequently, in practical feed formulation, DL-Methionine and L-Methionine can be substituted for one another on a weight-for-weight basis (kg per kg), without providing any additional advantages for L-Methionine.

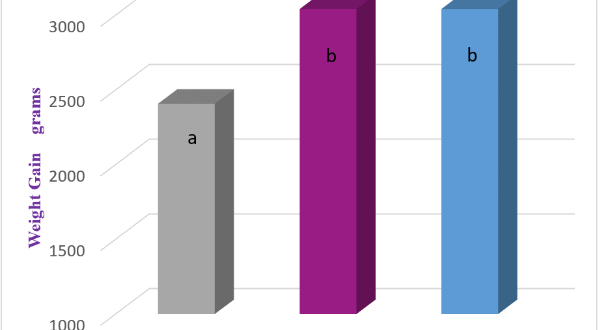

Table 1 Nutritional Value studies in broilers 2015; University of Pannonia, Keszthely, Hungary DL-Methionine Versus L-Methionine on Growth rate

Body Weight

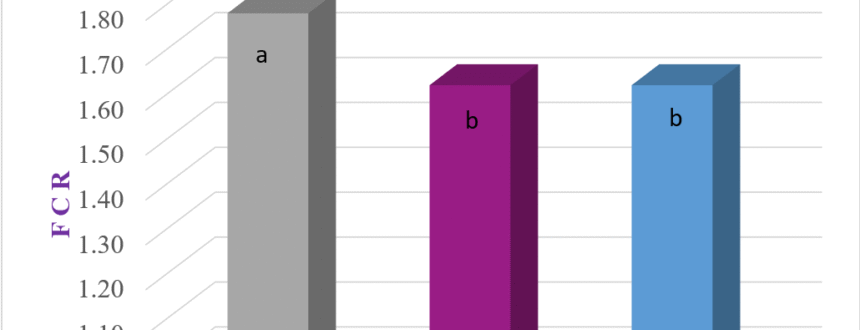

Table 1.1 Nutritional Value studies in broilers 2015; University of Pannonia, Keszthely, Hungary DL-Methionine Versus L-Methionine on FCR

- MHA –FA/HMTBa and MHA-Ca

MHA is available in a liquid form known as MHA-FA (Methoxy Hydroxy analogue free acid) or MHTBa (2-hydroxy-4-(methylthio) butanoic acid), as well as in powder form called MHA-Ca (Methoxy Hydroxy analogue calcium). Chemically, MHA is not classified as an amino acid; however, animals can convert it into methionine. When animals are fed MHA-FA (HMTBA) or MHA-Ca, they require additional nitrogen to enzymatically replace the hydroxyl group (HO-) with the amino group (H2N-), resulting in the formation of an amino acid that possesses complete nutritional value. The conversion process of MHA to Methionine does incur losses that adversely impact its biological effectiveness.

Hydroxy Analogue Free Acid (MHA-FA), often referred to as liquid MHA and chemically abbreviated as HMTBa, is composed of approximately 65% in monomeric form, 23% in dimer/oligomeric form, and the remaining 12% as water. The calcium salt of MHA-FA contains at least 84% methionine hydroxy analogue (MHA), a minimum of 12% calcium along with impurities, and a maximum of 2% water

Chemical composition of DL-Methionine, MHA-FA and MHA-Ca

DL-Methionine is a dry substance that contains at least 99% methionine and no more than 1% water. Chemically, MHA is not classified as an amino acid; rather, it serves as a precursor to methionine. This is due to the fact that MHA needs its hydroxyl group (HO) to be enzymatically substituted with an amino group (H2N) in order to create an amino acid that possesses complete nutritional value.

Chemical composition of DL-Met, MHA-FA and MHA-Ca

DL-Methionine is a dry substance that contains at least 99% methionine and no more than 1% water. Liquid MHA-FA is made up of 12% water and impurities, along with 88% of the methionine hydroxy analogue. It comprises 65% MHA monomers and 23% MHA dimers, oligomers, and other polymers. MHA-Ca consists of a minimum of 84% methionine hydroxy analogue (MHA), at least 12% calcium and impurities, and a maximum of 2% water.

DL-Met Versus MHA-FA and MHA-Ca

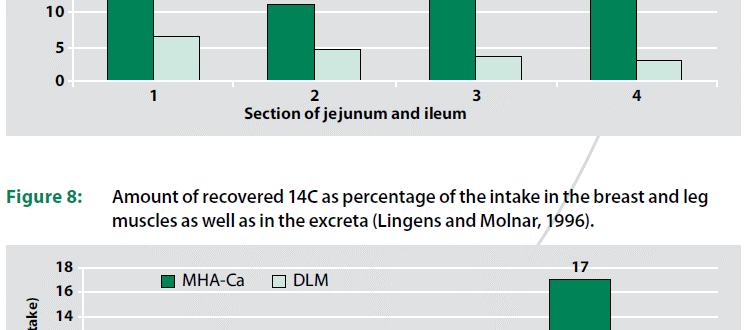

DL-Methionine serves as the primary global source of methionine utilized in animal feed. This is so because MHA is incorporated into muscle tissue with less efficiency due to a significant portion of MHA being lost through microbial degradation as well as MHA dimers and polymers exhibiting poor absorption. It has been established that MHA is not classified as an amino acid hence losses during the bio-conversion process are unavoidable. THE RELATIVE BIOLOGICAL EFFECTIVENESS (BE) OF MHA-FA/MHA-CA IN COMPARISON TO DL-MET IS 65% ON A PRODUCT-TO-PRODUCT BASIS. (BE) is defined as the amount of product B needed to substitute product A to achieve equivalent effects, responses, or performance.

The rate and degree of absorption vary among different sources of methionine; notably, MHA polymers exhibit slow and limited absorption. When the methionine source is not absorbed quickly, it can be utilized by intestinal micro-organisms instead of the bird. There is substantial evidence indicating that intestinal micro-organisms transform MHA into other compounds that the bird cannot utilize. In contrast, with a significantly faster and more complete absorption, the degradation of methionine is considerably lower compared to MHA products

The application of simultaneous dose response trials is a legitimate approach. Consistently, the findings indicate that the relative Bioefficacy (BE) of MHA products is considerably lower than the theoretical maximums (88 / 84%). ALL DATA SUGGESTS A BE OF APPROXIMATELY 65%, IN COMPARISON TO DL METHIONINE. Utilizing an internal marker – like diluted DL Methionine – enhances the reliability of this conclusion

When choosing a methionine source for livestock, it is important to take into account factors such as bioavailability, cost-effectiveness, and any additional benefits that may arise from basic methionine supplementation. Both dry crystalline methionine (DLM) and methionine hydroxy analog (MHA) are suitable choices; however, DLM, particularly MetAMINO®, is frequently favored due to its high purity, bio-efficacy, and ease of handling.

The Evonik technical team in East Africa is eager to engage in further discussions on this subject and provide assistance with practical applications, including detailed ration formulation, ingredient analysis, and guidance on sourcing MetAMINO®, in East Africa. Please do not hesitate to reach out to me via email at john.owaga@evonik.com or by phone at +245724321421.